What Makes Colback the best carrier for Bituminous Membranes?

For bituminous membranes to be durable yet cost-effective, they require carrier materials and inlays which combine low weight and thickness with excellent mechanical properties. The Colback Nonwovens portfolio of reinforced nonwovens has been designed for use across a broad range of hot impregnation and coating processes, which require a strong fabric with high dimensional stability and reinforcement capacity, making it the perfect carrier for bituminous membranes.

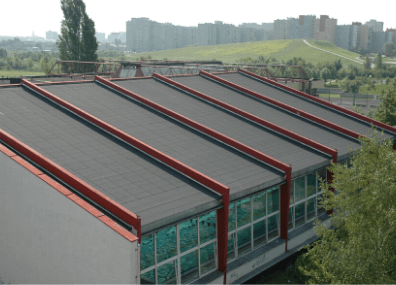

Colback spunbond nonwovens provide superior strength and stability. They facilitate the fabrication of high-performance waterproofing membranes while supporting process efficiency. Colback is easy to apply and accommodates angles and curves. These are the characteristics that make the non-woven suitable for use in membranes for new and renovation construction alike.

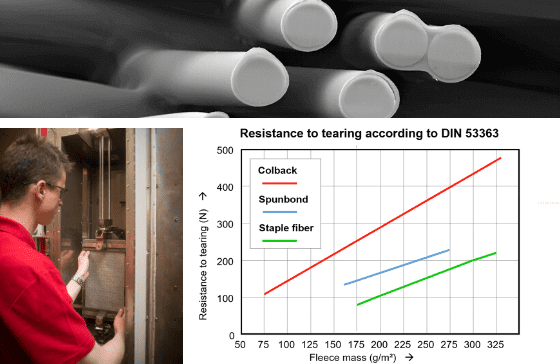

Unrivaled Tensile Strength and Tear Resistance

Colback nonwovens for bitumen membranes are the result of a unique, highly flexible two-step production technology. It involves spinning endless bi-component filaments consisting of a polyester core and a polyamide sheath.

The filaments are thermally bonded to form a non-woven matrix, free of chemical binders delivering unrivalled tensile and tear strength as well as tear resistance. The polyamide sheath ensures excellent adhesion to bitumen and coatings.

Superior End-Product Stability

Colback nonwovens are strong and stable.

The waterproofing membranes in which you use them to reinforce also have exceptional stability- making them easier to cut and handle. Additionally, Colback nonwovens open structure guarantees ease and speed of impregnation, coating and full saturation. Its outstanding evenness of mass contributes to maximum operational efficiency.

Good to know: Colback membranes have the same physical properties in all directions, so they’re easy to handle in a broad range of applications.

Examples of applications using Colback Nonwovens:

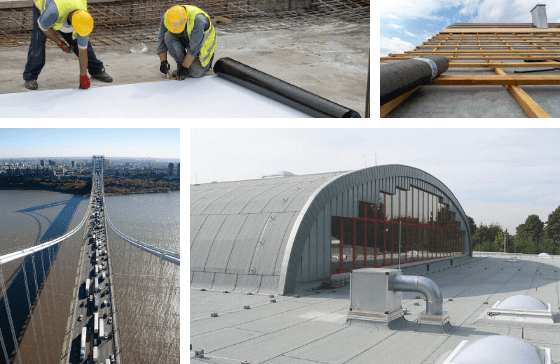

- Roofing membranes

- Roof underlayments

- Foundation waterproofing membranes

- Bridge deck and mine waterproofing membranes

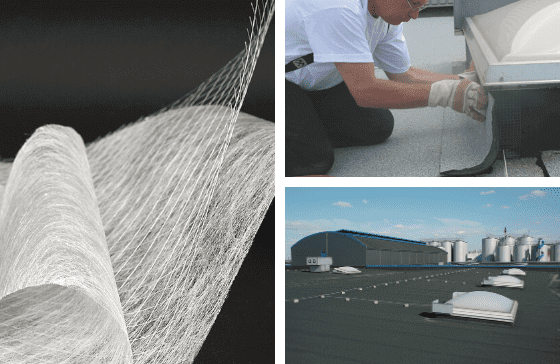

The Colback portfolio includes a comprehensive range of reinforced product variants.

Parameters such as physical compatibility, surface tension or elongation can be adapted to match your specific performance needs. Colback is available with glass scrim reinforcement, glass fleece reinforcement for improved fire resistance or a combination of scrim and fleece.

Key Features

- High tensile strength at low weight

- Open thermally bonded structure

- Excellent dimensional stability

- High thermal stability

- Isotropic

- Good affinity to bitumen

- Outstanding tear resistance

- Excellent evenness of mass

- Thermally bonded (i.e. free of chemical binder)

Key Benefits

- Facilitates production of thin, yet strong membranes resulting in longer roll lengths

- Often allows significant savings in bitumen: saves costs and less cooling capacity needed

- Easy and predictable to process

- Optimizes production yield

- Supports fast and consistently high saturation with bitumen

- Superior end product stability

- Low weight end-product

- Optional glass fleece for enhanced fire retardancy

Download Brochure

Need more information? Discover the capabilities of Colback Nonwovens that make it the preferred carrier and reinforcement for bitumen membranes! Fill out the form & download the brochure now!

Gallery