WHAT MAKES COLBACK Nonwoven fabric AN EXCELLENT CARRIER FOR CONSTRUCTION MEMBRANES?

High-performance construction membranes are made with monolithic polymer coatings or films. For high-performance membranes to be durable yet cost-effective, they require a carrier that bonds well with the coating or film and is easy to process.

Thanks to the unique Colback technology the Colback nonwoven fabrics can be optimized to match the coating or film specification. This often leads to easier processing while saving on coating or glue. Additionally, the finished product is thin, stiff, isotropic and very easy to cut. This makes construction membranes with Colback nonwovens inside an absolute winner.

Designed to meet your needs

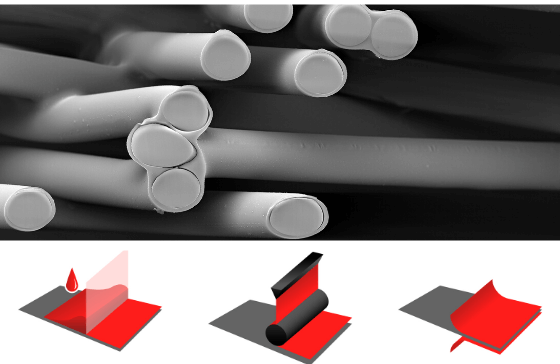

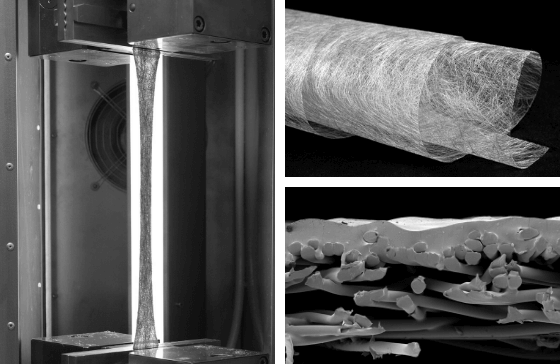

Colback nonwovens are a unique composition of endless bi-component filaments with a polyester core and a polymer sheath. The filaments are thermally bonded (binder-free) into a nonwoven matrix which is the foundation of the unrivalled tensile and tear strength. Parameters such as sheath polymer, filament diameter and tensile strength can be varied so that product properties can be adapted to match your specific performance and processing needs.

KEY ADVANTAGES:

- Excellent strength/weigth ratio for thinner membranes and more m2/roll

- High nail tear resistance yet easy to cut

- High dimensional stability

- Uniform fleece for trouble free/high speed coating

- No glue = open and VOC free

- Stiff & isotropic = easy to handle

- Easy to cut

- Often helps saving coating or glue costs

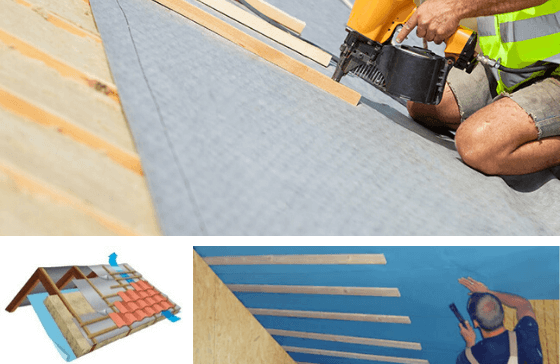

EXAMPLES OF CONSTRUCTION MEMBRANES WITH COLBACK NONWOVENS

- Roofing underlayment or underslating

- Wind barrier/breather (also known as House wrap)

- Air and Vapor control layer (AVCL)