A new innovative liquid applied membrane (waterproofing membrane) for the building markets was introduced in China last August.

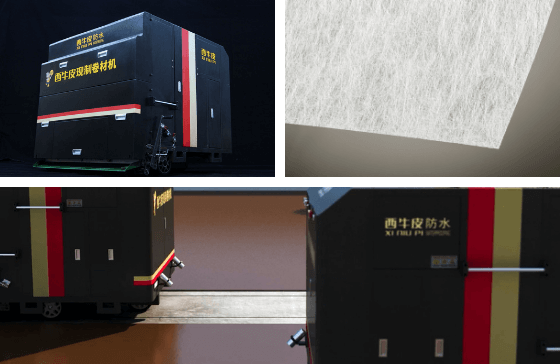

The product is the result of an intensive collaboration between Xiniupi Waterproof Technology Co., Ltd (XNP) and Low & Bonar over four years.

Low & Bonar’s Colback nonwoven fabrics are a critical component for this liquid applied membrane by XNP.

Liquid applied membranes, also referred to as LAM’s, are used in many waterproofing applications in Building and Construction. They are cast in-situ with different types of coating materials.

In the LAM system, Colback nonwoven fabrics function as a highly beneficial reinforcing material on which the coating is directly applied. Colback is extremely suitable for this purpose because – amongst others – it allows for fast and secure impregnation and saturation.

It features high strength at low weight and thickness as well as high elongation, resulting in a very stable end product with a long lifetime.

To maximize its performance, XNP and Low & Bonar worked closely together to realize the optimal carrier/coating match for XNP’s LAM, which includes a machine applied graded rubber coating.

With much-dedicated involvement of the R&D team and Production, the Colback nonwoven material was tailored exactly to the purpose.

Beyond product development, the partnership extended to establishing the accompanying product standardization and fulfilling marketing engagements in China.

XNP celebrated their product launch at a special Waterproofing Innovation Seminar, supported by the China Engineering Construction Standardization Association where it was presented together with Low & Bonar as a joint development between the companies.

Leaders and experts in the industry, as well as industry elite scholars, recognized the new XNP system as of today’s benchmark in the industry.

Interested in more information about liquid applied membranes with Colback nonwoven fabrics?