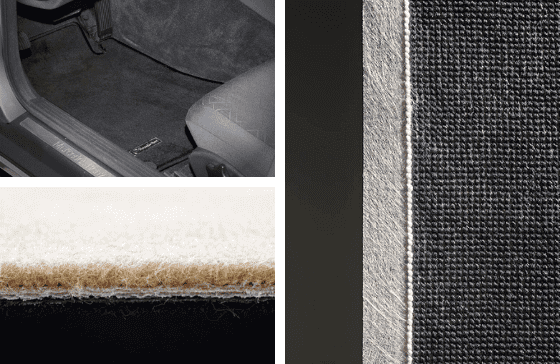

A key demand for optional mats is that they lie flat and stay flat during their service life even though exposed to heavy use. The primary backing for tufting plays a critical role in delivering the required properties.

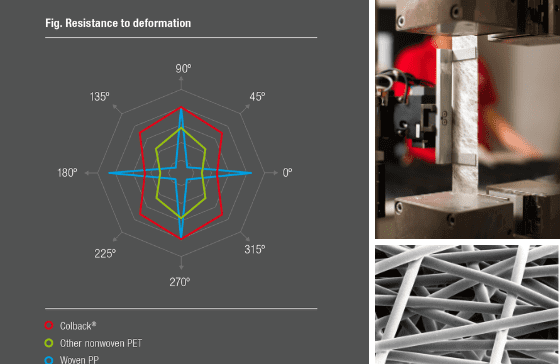

Thanks to their particularly high stability, Colback non-wovens prevent bowing and curling. Colback facilitates a strong tuft bind and abrasion resistance of the finished mat. Colback’s excellent tear strength and tufting characteristics mean that the same high performance can often be achieved with a lower weight primary backing.

Key Features

• Thermally bonded open filament structure

• Homogeneous filament distribution and high bonding quality

• Excellent dimensional and thermal stability

• High rigidity

• Consistent high performance from roll to roll and batch to batch

• Grades with up to 100% recycled content available

Key Benefits

• Contributes to process stability during tufting and pre-coating

• Supports consistent appearance of the face yarn

• Provides outstanding stitch holding

• Facilitates optimal penetration with latex: results in high pile anchoring and abrasion resistance

• Provides increased stiffness of the finished car mat

• Helps car mats stay flat

Download Brochure

Interested in learning more about Colback Nonwovens for molded car parts and other automotive applications? Fill out the form on the right and download the detailed info book now!