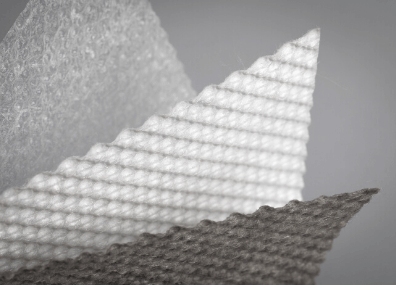

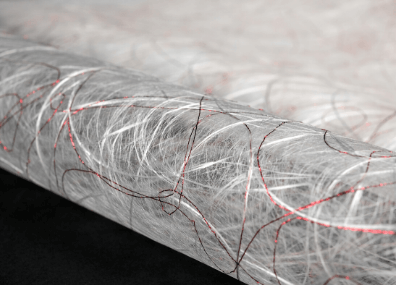

Colback is a range of high-performance spunbond nonwoven fabrics. For five decades already it has been used by clients in the most diverse industries. The product range encompasses a wide range of different product types. They all have been developed with the requirements of specific manufacturing processes and end-uses in mind.

HIGH-PERFORMANCE nonwoven material

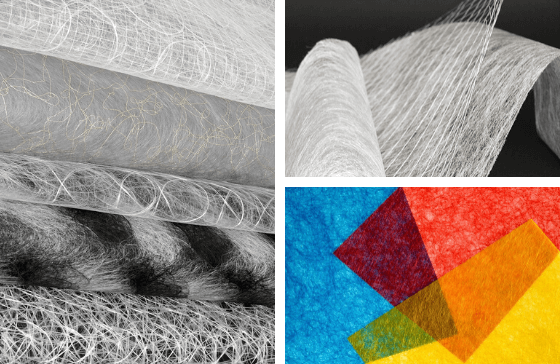

The physical and mechanical properties of Colback nonwoven fabrics can be tailored to meet a multitude of requirements. The standard portfolio includes seven different product categories. New variants are continually being added. Colback spunbond non woven fabrics have proven to excel in tufting, molding, coating and many other manufacturing processes.

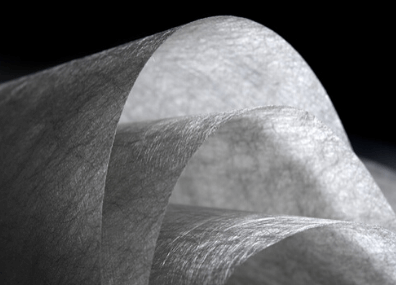

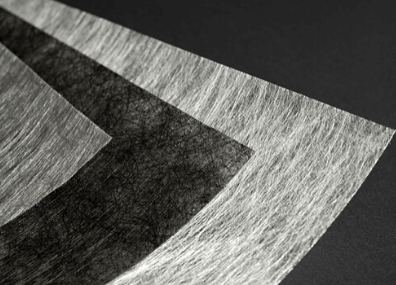

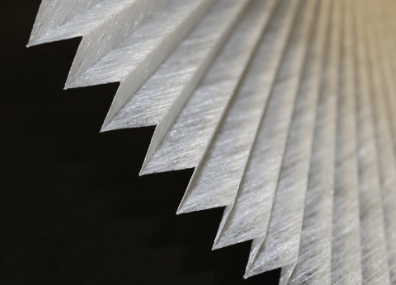

Amongst others, products produced on Colback fabrics take advantage of their outstanding stability, visual appearance and pleatability. Examples include high-end carpet tiles, wallcovering and air filters.

Nonwoven fabric DESIGNED TO MEET YOUR REQUIREMENTS

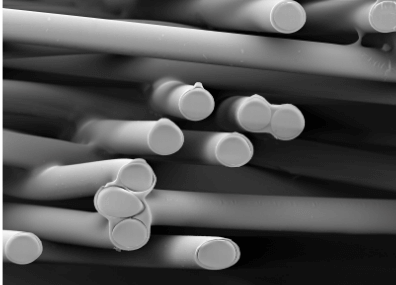

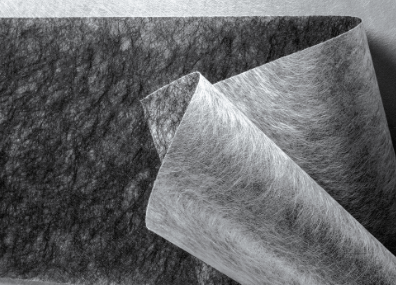

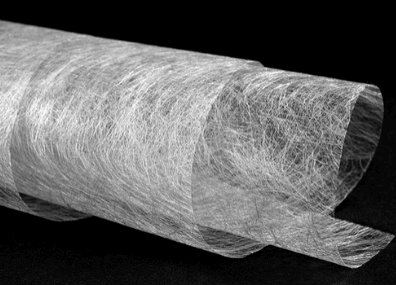

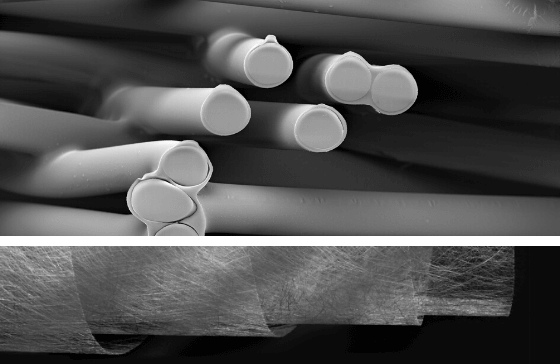

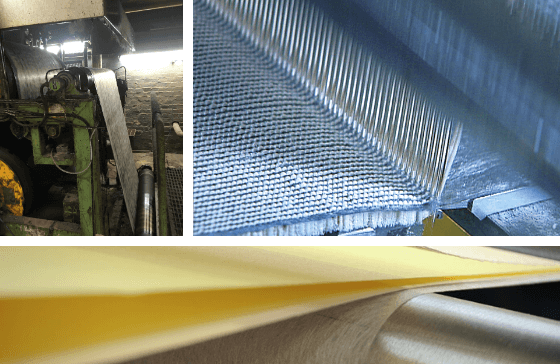

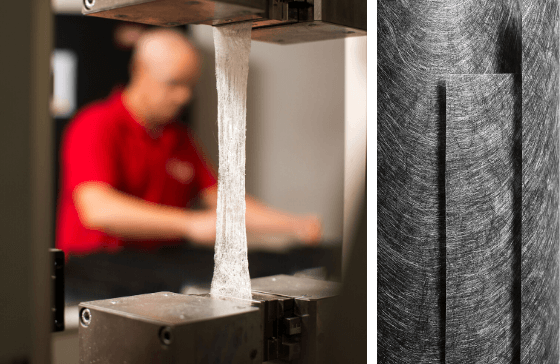

Colback nonwoven fabrics are produced by means of a proprietary highly flexible two-step manufacturing technology. It involves spinning endless bi-component filaments followed by a special laying-down and thermal bonding technique to form the finished fabric. It is this unique technology along with our thorough application expertise, which allows us to design Colback nonwovens to meet the needs of the most diverse industries.

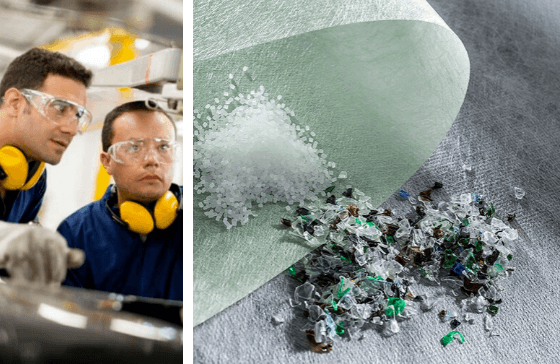

Parameters available to configure the fabric to individual process settings and end-uses include its strength, elongation, permeability and color. The bi-component filaments can be composed of different polymers.

We believe in the strength of long-term partnerships with our customers and want to be close to them. As such we are proud to have established Colback spunbond nonwoven manufacturing, sales and product development bases in North America, Europe and Asia.

Customers around the globe have confirmed time and again that they value Colback spunbond nonwovens for their consistently high quality from roll to roll and batch to batch. It contributes to high yield and helps them create class-leading durable products. Colback variants containing recycled polymers allow them to meet the demand for environmentally sustainable solutions.

NON-WOVEN SOLUTION FOR MANY PROCESSES

Over the past 50 years, Colback spunlaid nonwovens have proven their performance in a wide range of different manufacturing processes. A few examples:

Want to know more about manufacturing with Colback?

COLBACK PRODUCT FEATURES

What all Colback spunlaid nonwovens offer:

- High tear resistance

- Excellent dimensional stability

- Outstanding thermal stability

- High tensile strength

- Isotropy

- Non-fraying (even at the edges)

CONFIGURATION OPTIONS

To ensure that Colback nonwoven fabrics deliver exactly what you require for your individual manufacturing process and/or product design, a wealth of parameters can be tailored. Examples include:

|

|

COLBACK SPUNBOND NONWOVENS IN USE

The range of applications in which Colback spunbond nonwovens are applied is as manifold as is the product portfolio. The fabrics are serving customers around the world as:

At Freudenberg Performance Materials we are bringing together our established and successful technologies – Colback®, Enka® solutions, Evolon®, Karbofil and Lutradur® –

under our new future-focused umbrella brand, Filtura to create a uniquely powerful, integrated product portfolio.

Benefit from the reliability you’ve become accustomed to from a strong partner.

More Information

Intrigued by the versitality of Colback and interested in discovering how Colback Nonwovens can benefit you? Fill out the form on the right and download the detailed info book now!