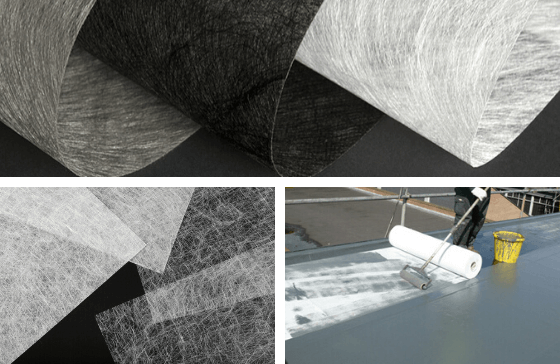

WHAT MAKES COLBACK AN EXCELLENT fleece FOR Liquid applied systems?

Colback fleece makes Liquid Applied Membrane system installation easier and faster without making compromises to the quality. Colback can be specially engineered to match specific waterproofing coatings. Colback is easy to cut, does not wrinkle, is easy to position and allows for very quick saturation without air pockets. Additionally Colback fleece helps improving puncture resistance.

Why are Liquid Applied Waterproofing Systems used

A Liquid Applied Waterproofing Membrane system (LAM) is a monolithic, fully-bonded, liquid-based coating suitable for many waterproofing and roofing applications. The coating cures to form a elastomeric waterproof membrane and may be applied over many substrates, including asphalt, bitumen and concrete.

LAM’s are gaining popularity all over the world because of their ease , versatility and speed in installation/application

Architects like LAM systems as they provide a solution for new builds as well as for renovations of roofs and podium decks. Contractors like to work with LAM systems because of the ease and speed of installation over sheet-applied waterproofing membranes.

To best match the different substrates there are multiple coating systems ranging from Acrylic, Polyurethane, Rubber, Bituminous to hybrid combinations. In most situations a fleece is used to control the coating thickness, for strengthening and crack bridging.

How Liquid Applied Membrane systems can benefit from Colback nonwoven fabrics

While the coatings systems are carefully developed often a standard fleece type is used. This is odd as the saying ‘birds of a feather stick together’ also applies to the coating and fleece. To truly benefit from the ease and speed it is important to use a fleece that works well with the coating. Only then the benefits of a Liquid Applied Membrane system are used to their full potential.

Colback fleeces can be engineered to make LAM system installation even easier and faster without making compromises to the quality. Colback technology provides design flexibility which is unrivalled in the nonwoven industry. Physical compatibility, tensile strength and stiffness are just a few examples of the many properties that can be tailored. Thanks to the Colback versatility we can offer the optimal fleece type to match your specific coating system. The right fleece will have a synergetic effect to your system making it perform to its full potential – both during installation as well as throughout its service life.

Key installation benefits

- Easy to cut and position

- No folds, wrinkles or deformation

- Full and fast saturation without air pockets

- Non-itching, skin friendly

- Easy handling like paper with high-end nonwoven performance.

Key technical features

- Engineered to work well with specific coatings

- High tear strength and tear-propagation resistance

- High elongation at break

- Uniform